Discover how Dongil Printing Service streamlined cleaning, cut resource use, and maintained top...

Flexo Wash offers innovative and high-quality cleaning solutions to satisfy individual needs of printers worldwide. Through our solutions we ensure you consistent print quality and high productivity with focus on safe working conditions and sustainability. With 30 years of developing innovative cleaning technology, we cover all types of cleaning machines for both solvent and non-solvent cleaning liquids – and latest also laser cleaning units as a waste free alternative.

Let us guide you on your journey towards higher print quality!

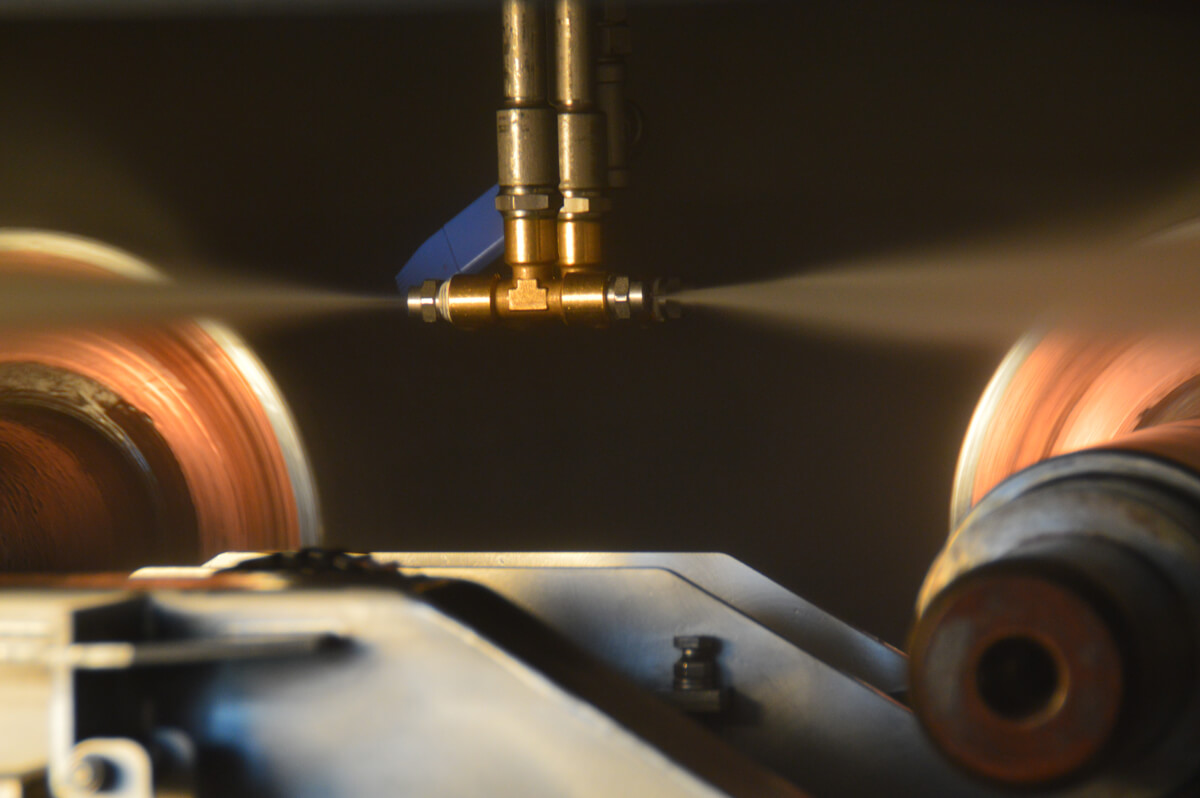

Plastic film is widely used in various industrial applications and has become a significant environmental concern due to its contribution to plastic pollution. At Flexo Wash, we understand the printing industry's struggle of having dirty printed film and having to get rid of it.

Flexo Wash did the 30th of April showcase our newest solution during a live product launch of our Film Cleaner. Our mission with this Film Cleaner is to extend the lifespan of printing film, reducing waste, cost savings, and environmental impact.

Discover how Dongil Printing Service streamlined cleaning, cut resource use, and maintained top...

Written by Dea Jaqué

A Scandinavian customer in a Swedish packaging company known for its sustainable and innovative...

Written by Dea Jaqué

In today’s competitive printing landscape, every minute of downtime costs money, and every quality...

Written by Dea JaquéClick the buttons for contact regarding service or liquids - else please fill in the form below and let us know how we can help you.

Please fill in the form below and let us know how we can help you.

Please fill in the form below and let us know how we can help you.